There are various types of electrical wires and cables, each with their own specific uses. These include coaxial cable, metal-armored cable, fiber-optic cable, direct-buried cable, ribbon cable, twisted pair, aluminum building wiring, submersible cable, and more.

These wires and cables are used in different applications and industries for the transmission of electrical power and signals.

Single Conductor Wire

Single conductor wire, also known as single strand wire, is one of the main types of electrical wires. It consists of a single wire that is used to carry electrical current from one place to another. Single conductor wire is commonly used in various electrical applications, such as household wiring, automotive wiring, and electrical equipment.

Explanation And Uses:

Single conductor wire, also known as single-strand wire, is a type of electrical wire that consists of a single conductor or wire. It is typically made of copper or aluminum and is used for various electrical applications. Here are some key points to understand about single conductor wire and its uses:

- Single conductor wire is commonly used for electrical wiring in residential, commercial, and industrial buildings. It is used to connect electrical devices, fixtures, and outlets to the main electrical supply.

- It is also used in automotive applications, where it is used for wiring circuits in cars, trucks, and motorcycles.

- Single conductor wire is available in different gauges or thicknesses, which determine its electrical current carrying capacity. Thicker gauges are used for higher current applications, while thinner gauges are suitable for lower current applications.

- It is important to match the gauge of the single conductor wire with the electrical load requirements to ensure safe and efficient operation.

- Single conductor wire is insulated to protect against electrical shocks and short circuits. The insulation material can vary, with options such as PVC (polyvinyl chloride), XLPE (cross-linked polyethylene), or Teflon.

- The insulation on single conductor wire may also be color-coded for easy identification of the wire’s purpose or function.

- Single conductor wire can be installed using various methods, including conduit wiring, surface-mounted wiring (casing and capping), or concealed wiring (cleat wiring, batten wiring, lead sheathed wiring).

- It is important to follow electrical codes and regulations when installing single conductor wire to ensure safety and compliance.

- Single conductor wire is essential in building and maintaining electrical systems, providing reliable power distribution for various applications.

- When selecting single conductor wire, factors such as insulation type, current carrying capacity, and application requirements should be considered to ensure the correct wire is used for the intended purpose.

Single conductor wire is a fundamental component of electrical systems, used in a wide range of applications. Its flexibility, durability, and electrical conductivity make it an essential element in powering our homes, offices, and industries.

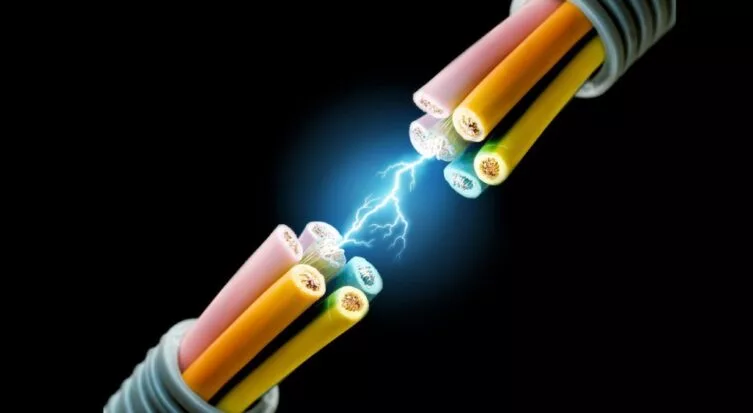

Multi-Conductor Wire | Electrical Wires And Cables

Multi-conductor wire, also known as stranded wire, is a type of electrical wire that consists of multiple smaller wires bundled together. It is commonly used in applications where flexibility and durability are required, such as electronics, appliances, and automotive wiring.

Electrical Wires And Cables

A multi-conductor wire is an electrical wire that consists of multiple strands or conductors within a single cable. This type of wire is commonly used in various electrical applications due to its versatility and convenience. Here are some key points to understand about multi-conductor wire:

- Explanation and uses:

- The multi-conductor wire is designed to carry multiple signals or electrical currents simultaneously, making it ideal for applications that require multiple connections or circuits.

- It is commonly used in industries such as telecommunications, audio systems, security systems, and computer networking to transmit data, signals, or power to different devices or components.

- This type of wire is flexible and easy to handle, allowing for easy installation and maintenance. It is often preferred in situations where a single cable with multiple conductors is more practical than running multiple individual wires.

- Multi-conductor wire comes in various configurations, such as twisted pairs, shielded or unshielded cables, and flat ribbon cables. Each configuration has its specific uses and benefits depending on the application requirements.

- Twisted pairs are commonly used for data transmission and are designed to minimize electromagnetic interference (EMI). They are often used in Ethernet cables and telephone cables.

- Shielded cables offer additional protection against EMI by incorporating a protective layer, such as foil or braided shielding, to minimize interference from external sources. They are used in applications where signal integrity is critical, such as control systems and audio/video applications.

- Unshielded cables, on the other hand, are suitable for less sensitive applications or short distances where EMI is not a major concern.

- Flat ribbon cables are used in applications where space is limited, such as internal wiring in computers, printers, or flat-panel displays.

- Overall, multi-conductor wire provides a reliable and efficient solution for transmitting multiple signals or power in various electrical systems and applications.

Remember, when it comes to selecting the right type of wire for your specific application, it is important to consider factors such as the number of conductors required, the type of signals or power that needs to be transmitted, and any environmental factors that may affect the wire’s performance.

So, choose wisely to ensure optimal functionality and performance in your electrical systems.

Single, Two, And Three-Core Cables | Electrical Wires And Cables

Single, two, and three-core cables are types of electrical wires used for various applications. These cables consist of individual conductors that can carry electric currents and are commonly used for power distribution and transmission purposes.

Explanation And Uses Of :

Single, two, and three-core cables are commonly used in electrical installations for different purposes. Here is a breakdown of their explanation and uses:

Single-Core Cables:

- Single-core cables consist of a single conductor wire, usually made of copper or aluminum.

- These cables are primarily used for high-voltage transmission and distribution of electricity.

- Single-core cables are commonly used in overhead power lines and underground electrical systems.

- Due to their high conductivity, they are efficient in delivering power over long distances.

Two-Core Cables:

- Two-core cables consist of two conductors, usually insulated and twisted together.

- These cables are commonly used for household wiring, such as lighting circuits and electrical appliances.

- They are also suitable for low voltage applications, providing a reliable connection for power supply.

- Two-core cables are often used in residential and commercial buildings, ensuring safe and efficient electrical connections.

Three-Core Cables:

- Three-core cables consist of three conductors, typically insulated and grouped.

- These cables are commonly used for three-phase electrical systems, which are prevalent in industrial and commercial settings.

- Three-core cables provide a balanced distribution of electrical load and ensure efficient power transmission.

- They are also used for heavy-duty applications, such as powering large machinery and equipment.

Single, two, and three-core cables have their specific uses based on the type of electrical system and application. Whether it is high voltage transmission, household wiring, or industrial power supply, these cables play a crucial role in ensuring safe and reliable electrical connections.

Credit: www.homedepot.com

Armored Wire | Electrical Wires And Cables

Armored wire, also known as armored cable, is a type of electrical wire that is encased in a protective layer, usually made of metal, to provide extra durability and protection against physical damage. It is commonly used in applications where the wire needs to be installed underground or in areas with a high risk of damage.

Armored wire, also known as armored cable, is a type of electrical wire that is reinforced with a layer of protective armor. This armor provides additional durability and resistance to damage, making it ideal for installation in harsh environments or areas where the wire may be exposed to potential hazards.

Here are some key points about armored wire and its uses:

- Armored wire is commonly used in industrial settings, construction sites, and outdoor installations where the wire may be exposed to moisture, chemicals, or physical damage.

- The protective armor of the wire is typically made of a strong metal, such as steel or aluminum, which provides excellent protection against abrasion, impact, and crushing.

- Armored wire is available in various types, including armored power cables, armored control cables, and armored instrumentation cables, each designed for specific applications.

- This type of wire is often used for underground wiring or in conduit systems, where it needs to withstand mechanical stress, extreme temperatures, and even rodent attacks.

- Armored wire is commonly used in high-risk areas, such as industrial plants, oil and gas refineries, and mines, where electrical installations require extra protection against potential hazards.

- In addition to its protective properties, armored wire also offers enhanced electrical performance, including better resistance to electromagnetic interference (EMI) and reduced signal loss.

- Armored wire is a reliable and cost-effective solution for ensuring the safety and longevity of electrical installations in demanding environments.

To summarize, armored wire is a type of electrical wire that is reinforced with a layer of protective armor, making it highly durable and resistant to damage. It is commonly used in industrial settings, construction sites, and outdoor installations where it may be exposed to harsh conditions.

The protective armor provides excellent resistance to abrasion, impact, and crushing, while also offering enhanced electrical performance. Armored wire is a reliable choice for ensuring the safety and longevity of electrical installations in challenging environments.

Coaxial Cable

Coaxial cable is a type of electrical wire commonly used for transmitting high-frequency signals in telecommunications and television systems. It consists of a central conductor surrounded by an insulating layer, a metallic shield, and an outer protective covering.

Coaxial cables are a type of electrical cable widely used for transmitting audio, video, and digital signals. They consist of a central conductor surrounded by an insulating layer, a shield, and an outer insulating jacket. Here are some key uses and features of coaxial cables:

- High-quality signal transmission: Coaxial cables are known for their excellent transmission capabilities, making them ideal for applications that require high-quality signals, such as television broadcasting or internet connections.

- Wide frequency range: Coaxial cables can handle a wide range of frequencies, from low-frequency signals like analog audio to high-frequency signals like broadband internet.

- Protection against electromagnetic interference (EMI): The shield in coaxial cables helps protect against EMI, ensuring signal integrity and reducing noise interference.

- Long-distance transmission: Coaxial cables are capable of transmitting signals over long distances without significant signal degradation.

- Versatile applications: Coaxial cables are used in various industries and applications, including television and radio broadcasting, cable television (CATV), closed-circuit television (CCTV), computer networks, and telecommunications.

Coaxial cables are a popular choice for transmitting high-quality signals over long distances while protecting against electromagnetic interference. They are widely used in broadcasting, networking, and telecommunications industries, among others.

Metal Armoured Cable | Electrical Wires And Cables

Metal Armoured Cable is a type of electrical wire that is encased in protective metal armor, providing extra strength and durability. It is commonly used in outdoor applications or areas where the cable needs protection from physical damage.

Metal Armoured Cable is a type of electrical cable that is specifically designed to provide extra protection in environments where there is a risk of mechanical or physical damage. This cable is known for its durability and strength, making it suitable for a wide range of applications.

Explanation And Uses:

- Metal Armoured Cable consists of a metal sheath that provides a protective layer around the inner conductors. This sheath is usually made of steel or aluminum, which helps to protect the cable from impact, compression, and other external forces.

- The metal sheath enhances the cable’s resistance to moisture, chemicals, and extreme temperatures, making it ideal for use in outdoor and harsh environments.

- Metal Armoured Cable is commonly used in commercial and industrial settings, such as power plants, construction sites, and manufacturing facilities, where there is a higher risk of damage to the cables.

- This type of cable is often used for underground wiring, as it provides additional protection against moisture and physical damage caused by digging or heavy machinery.

- Metal Armoured Cable is also popular for wiring installations in buildings that require fire resistance. The metal sheath helps to prevent the spread of fire and acts as a barrier against the release of toxic gases.

- In addition to its protective features, Metal Armoured Cable is also suitable for carrying higher voltages and currents, making it ideal for power distribution applications.

Overall, Metal Armoured Cable is a reliable and robust choice for electrical installations that require extra protection against mechanical damage, moisture, fire, and other external factors. Its versatility and durability make it a popular option for various industries and environments.

Fiber-Optic Cable

Fiber-optic cables are a type of electrical wire used for high-speed data transmission. Unlike traditional copper cables, fiber-optic cables use light to transmit signals, making them ideal for long-distance and high-bandwidth applications.

Fiber-optic cable is a type of electrical cable that uses thin strands of glass or plastic to transmit data and signals using pulses of light. It offers high-speed and bandwidth capabilities, making it ideal for long-distance communication and networking applications.

Here are some of the key features and uses of fiber-optic cable:

- Faster Data Transmission: Fiber-optic cable provides significantly higher data transmission speeds compared to traditional copper cables. It can transmit data at speeds up to several terabits per second, making it suitable for applications that require fast and reliable data transfer, such as internet connections and telecommunications.

- Long-Distance Communication: One of the major advantages of fiber-optic cable is its ability to transmit signals over long distances without significant loss of quality or strength. Unlike copper cables, which are subject to signal degradation over long distances, fiber-optic cables can transmit signals over hundreds of kilometers without the need for signal repeaters.

- Immunity to Electromagnetic Interference: Fiber-optic cables are not affected by electromagnetic interference, which can disrupt or degrade signals in traditional copper cables. This makes fiber-optic cables highly reliable and suitable for use in environments with high levels of electromagnetic interference, such as industrial settings or areas with heavy electrical equipment.

- Secure Data Transmission: Fiber-optic cables offer enhanced security for data transmission. Since they use light signals to transmit information, it is difficult to tap into or intercept the signals, providing a higher level of protection against unauthorized access or data breaches. This makes fiber-optic cables particularly suitable for applications that require secure data transmission, such as government networks, financial institutions, and healthcare facilities.

- Versatility in Application: Fiber-optic cables are used in various industries and applications, including telecommunications, internet service providers, data centers, broadcasting, medical imaging, and military communication. They are also commonly used for high-speed internet connections, cable TV networks, and telephone systems.

Fiber-optic cable is a high-performance type of electrical cable that offers fast data transmission, long-distance communication capabilities, immunity to electromagnetic interference, secure data transmission, and versatility in application. Its unique characteristics make it an essential component in modern communication and networking infrastructures.

Direct-Buried Cable | Electrical Wires And Cables

Direct-buried cables are a type of electrical wires that are designed to be installed directly into the ground without the need for a conduit or any other protective covering. They are commonly used for outdoor applications such as underground power distribution, telecommunication, and fiber-optic networks.

Explanation And Uses:

Direct-buried cables are a type of electrical wire that is designed to be installed directly into the ground without the need for conduit or tubing. These cables are typically used for outdoor applications where burying the cables underground is necessary for protection and aesthetics.

Here are the main points to know about direct-buried cables:

- Weather-resistant: Direct-buried cables are resistant to weather conditions such as rain, snow, and extreme temperatures, making them ideal for use in outdoor environments.

- Durable and long-lasting: These cables are built to withstand the rigors of being buried underground, ensuring long-term reliability and minimal maintenance requirements.

- Protection against physical damage: Buried cables are protected from physical damage caused by things like rodents, excavation work, and vehicular traffic.

- Versatile applications: Direct-buried cables are used in a variety of applications, including residential, commercial, and industrial projects. They are commonly used for outdoor lighting, underground power distribution, and telecommunications systems.

Overall, direct-buried cables offer a convenient and reliable solution for outdoor electrical wiring needs, providing efficient power distribution and ensuring safety and protection in various applications.

Ribbon Cable

Ribbon cable is a type of electrical wire commonly used in electronic devices for connecting multiple conductors. It is flat and flexible, making it ideal for applications where space is limited.

Ribbon cables are a type of electrical wire that consists of multiple conductors arranged in a flat, ribbon-like shape. They are commonly used in electronics and computer systems where space is limited and organized wiring is necessary. Here are some key points about ribbon cables and their uses:

- Can contain a varying number of conductors, typically ranging from 10 to 64, although smaller and larger options are also available.

- Conductors are usually insulated with PVC or another insulating material.

- The flat design of ribbon cables allows for easy installation and organization within tight spaces.

- Ribbon cables often have a color-coded system to help identify and connect specific conductors.

- They are commonly used for internal wiring in computers, printers, televisions, and other electronic devices.

- Ribbon cables are also used in industrial settings for connecting control panels, PLCs (Programmable Logic Controllers), and other machinery.

- Their flat design makes them ideal for applications where a high density of connections is required, such as in data centers and server rooms.

- Ribbon cables are generally not meant for environments with heavy vibrations or extreme temperatures, as they may be more prone to damage.

- They provide a neat and organized appearance compared to traditional round cables, making troubleshooting and maintenance easier.

Ribbon cables are a versatile wiring option, providing a flat and organized solution for various electronic and industrial applications. Their use helps streamline connections while saving space, making them a popular choice in many industries.

Twisted Pair

One of the types of electrical wires and cables commonly used is twisted pair. Twisted pair cables consist of two insulated conductors twisted together, which helps reduce electromagnetic interference. They are often used in telecommunications and computer networking applications.

Types Of Electrical Wires And Cables And Their Uses:

When it comes to electrical wires and cables, one type that is commonly used is the twisted pair. This type of cable is made up of two insulated wires twisted together in a helical pattern. Twisted pair cables are known for their efficient transmission capabilities and are widely used for both residential and commercial applications.

Let’s dive into an explanation of twisted pair cables and their uses:

- Twisted pair cables consist of two insulated copper wires that are twisted together to reduce electromagnetic interference. The twisting of the wires helps to cancel out any external signals and minimizes cross-talk between neighboring cables.

- The wires in a twisted pair cable are often color-coded, with one wire being solid and the other striped. This makes it easier to identify and connect the wires correctly during installation.

- Twisted pair cables come in two main categories: Unshielded twisted pair (UTP) and shielded twisted pair (STP). UTP cables are commonly used for Ethernet networking, telephone systems, and audio/video applications in homes and offices. STP cables, on the other hand, have an additional metal shield around the twisted wires, providing extra protection against electromagnetic interference.

- One of the key uses of twisted pair cables is in Ethernet networking. They are commonly used to connect computers, routers, switches, and other network devices. Twisted pair cables support data transfer rates from 10 Mbps to 10 Gbps, making them ideal for high-speed networking.

- Another use of twisted pair cables is in telephone systems. They are used to connect telephones to telephone lines, providing clear and reliable voice communication. Twisted pair cables are also commonly used in intercom systems, security systems, and other audio applications.

- Twisted pair cables are often preferred for their flexibility and ease of installation. They can be easily bent, routed, and terminated, making them suitable for various wiring configurations.

- In addition to their use in networking and telecommunications, twisted pair cables can also be found in audio and video applications, such as connecting speakers, microphones, and CCTV cameras.

Twisted pair cables are a versatile and widely used type of electrical wire. They provide effective transmission capabilities, reduce electromagnetic interference, and are suitable for a range of applications including Ethernet networking, telephone systems, and audio/video connections. When it comes to reliability and efficiency, twisted pair cables are a go-to choice for many electrical installations.

By following the best practices and guidelines, you can ensure that your electrical wiring project is up to standard and meets all safety requirements. Whether you are setting up a network in your home or office, or installing a telephone system, opting for twisted pair cables will help ensure a stable and efficient electrical connection.

Aluminum Building Wiring

Aluminum building wiring is a type of electrical wire used in construction projects. It is known for its durability, lightweight nature, and cost-effectiveness. This type of wiring is commonly used in residential and commercial buildings for various electrical applications.

Aluminum building wiring refers to electrical wiring that is made of aluminum conductors instead of copper. It was commonly used for residential and commercial buildings in the 1960s and 1970s. While aluminum wiring is less expensive than copper, it is also less conductive and more prone to certain issues.

Here is a breakdown of the explanation and uses of aluminum building wiring:

Explanation:

- Aluminum wiring is made up of aluminum conductors that carry electrical current.

- It was widely used between the 1960s and 1970s due to copper shortages and the rising price of copper.

- Aluminum wiring is less conductive than copper, meaning it carries electricity at a slower rate.

- It is also more prone to expansion and contraction, which can lead to loose connections over time.

- Loose connections in aluminum wiring can result in overheating and pose a fire hazard.

Uses:

- Aluminum building wiring is still present in older residential and commercial buildings.

- It is often found in branch circuits for lighting, receptacles, and appliances.

- Aluminum wiring is also commonly used for feeder circuits, which distribute electricity from the main electrical panel to the branch circuits.

- While aluminum wiring can still function properly if installed and maintained correctly, it is important to be aware of its potential issues and consider proper precautions.

Remember, if you have aluminum building wiring, it is wise to consult with a qualified electrician to assess its condition and ensure your electrical system is safe.

Submersible Cables

Submersible cables are a type of electrical wire that is designed to be used underwater, such as in pumps or in deep-sea applications. They are specially designed to withstand water pressure and provide reliable electrical connectivity in challenging environments.

Submersible cables are specialized electrical cables that are designed to operate underwater or in wet environments. These cables are commonly used for submersible pumps, underwater lighting systems, and other underwater electrical applications. Here are some key points about submersible cables:

- Waterproof Construction: Submersible cables are constructed with specialized materials that provide a high level of water resistance. They are typically made with a layer of insulation that is resistant to water and moisture, ensuring safe and reliable operation even when submerged.

- Strength and Durability: Submersible cables are designed to withstand the harsh conditions of underwater environments. They are typically made with durable materials that can resist corrosion, temperature variations, and mechanical stress.

- Flexible and Easy to Install: Submersible cables are often designed to be flexible and easy to install. This allows for easy routing and connection to submersible equipment, even in challenging underwater installations.

- Electrical Performance: Submersible cables are designed to provide efficient electrical performance even in wet conditions. They have excellent insulation properties to prevent electrical leakage and ensure optimal power transmission.

- Safety Considerations: Using the right type of submersible cable is crucial to ensure safety in underwater electrical installations. It is important to choose cables that are specifically designed for submersion and have proper insulation and waterproofing ratings.

- Various Applications: Submersible cables find applications in various industries, including agriculture, oil and gas, marine, and residential. They are commonly used in submersible pumps for irrigation, dewatering, and sewage handling. They are also used for underwater lighting and in aquariums.

Submersible cables are essential for electrical applications that require operating in wet or underwater environments. Their waterproof construction, strength, flexibility, and electrical performance make them suitable for a wide range of submersible installations. When choosing submersible cables, it is important to consider their specific application requirements and ensure proper insulation and waterproofing to ensure safe and reliable operation.

Frequently Asked Questions For Types Of Electrical Wires And Cables And Their Uses

What Are The 4 Types Of Electrical Wire?

The four types of electrical wire are coaxial cable, metal armored cable, fiber-optic cable, and direct-buried cable.

What Are The 3 Types Of Electrical Wires?

The three types of electrical wires are live wire, neutral wire, and earth wire.

What Are The 5 Types Of Electrical Wiring System?

The five types of electrical wiring systems include coaxial cable, metal armored cable, fiber-optic cable, direct-buried cable, and ribbon cable.

What Are Different Types Of Cables And Their Uses?

Different types of cables include coaxial cable, armored cable, fiber-optic cable, ribbon cable, twisted pair, and submersible cable. These cables are used for various purposes such as telecommunications, data networking, power transmission, and underwater applications.

What Are The Different Types Of Electrical Wires And Cables?

Electrical wires and cables include single conductor wire, multi-conductor wire, single, two and three-core cables, and armored wire.

Conclusion: Electrical Wires And Cables

To sum up, understanding the different types of electrical wires and cables and their uses is crucial for any electrical project. From single-conductor wires to multi-conductor cables, armored wires, and more, each type serves a specific purpose in delivering electrical power safely and efficiently.

Whether it’s for residential, commercial, or industrial applications, choosing the right wire or cable can ensure optimal performance and safety. So, before starting any electrical installation or repair, it’s important to identify the specific requirements and select the appropriate type of wire or cable.

With this knowledge at hand, electricians can confidently complete projects and meet the specific needs of their clients. By following standard wiring practices and adhering to electrical codes, professionals can ensure a reliable and long-lasting electrical system. Remember, always consult a qualified electrician for any electrical work to guarantee safety and compliance with regulations.