Why Don’T Underwater Welders Get Electrocuted: Underwater welders don’t get electrocuted because a layer of gaseous bubbles is created externally around the electrode to shield the electricity from the water. Underwater welding poses many dangers, including explosions, decompression sickness, and electric shock.

Because of the risks involved, underwater welding requires specific safety measures and specialized equipment to ensure the welder’s safety. Welders must also have the proper training, experience, and certifications to perform the job correctly.

Despite the risks, underwater welding is an essential component of offshore oil drilling, ship repair, and other projects that require welding in submerged environments.

We will delve deeper into how underwater welding works, the risks that come with the job, and the safety precautions that welders must take to avoid potential hazards.

Risks Of Underwater Welding

To prevent the risk of electrocution, underwater welders create a thick layer of gaseous bubbles around the electrode, covering the weld and shielding the electricity from water and corrosive gasses. Other risks of underwater welding include explosions from gas pockets and decompression sickness.

Welders need to use special waterproof equipment and be mindful of safety protocols. As an underwater welder, you face several risks that could result in severe injuries or even death.

These risks include gas explosions, decompression sickness, electric shock, and interruptions from sea life, among others. In this section, we’ll focus on the risks posed by gas explosions, decompression sickness, electric shock, and sea life interruptions.

Gas Explosions

Underwater welding involves heat, gas, and electricity, which can create a dangerous combination if not handled correctly. Hydrogen and oxygen can combine to form gas pockets, which can explode and cause severe injuries or death. The risk of gas explosions can be mitigated by ensuring proper ventilation and using the appropriate welding equipment.

Decompression Sickness

Decompression sickness, also known as “the bends,” occurs when a diver ascends too quickly from deep waters. The rapid change in pressure can cause nitrogen bubbles to form in the bloodstream, leading to joint pain, fatigue, and even death. Underwater welders must be trained to manage their ascent and descent properly to avoid this risk.

Electric Shock

Electric shock is a significant risk for underwater welders since water is a natural conductor of electricity. To prevent electrocution, a layer of gaseous bubbles is created externally around the electrode. This method covers the electrode, shielding the electricity from water and other oxidizing compounds.

Sea Life Interruptions

Sea life interruptions can be a nuisance and a minor risk for underwater welders. Although shark attacks are rare, they do happen, and underwater welders must take precautions to avoid them. Additionally, interruptions from sea animals such as dolphins or whales can pose hazards that require careful management.

In conclusion, underwater welding presents many risks that require specialized training, equipment, and precautions to mitigate the hazards. As an underwater welder, you must be aware of these potential dangers and take action to minimize your risk of injury or death.

Preventing Electric Shock

Underwater welders do not get electrocuted because the electricity is shielded from water and other oxidizing compounds using a thick layer of gaseous bubbles created externally around the electrode. This prevents electric shock, which is the biggest threat to their safety. Special waterproof equipment is also used for all underwater welding jobs.

Preventing Electric Shock

Underwater welding is a risky job that requires immense skills to keep the welder safe. The electric shock poses the greatest threat to underwater welders, and as such, they have to take necessary precautions to avoid it.

It is essential to note that electric current will always take the path of least resistance, and since water is a conductor of electricity, one would expect electric current to pass through the welder’s body. However, this is not usually the case as the following H3 headings explain how underwater welders prevent electric shock.

Isolated Circuit

To prevent electric shock, underwater welders use a method called a fully insulated electrode. Essentially, this electrode is made from a protective covering and then submerged into the water to make the circuit.

Only the cover is in contact with the water making the system isolated. This method is crucial as it helps reduce risks of electric shock or electrocution from stray currents from other sources.

Thick Gaseous Bubble Shield Another method used to prevent electric shock in underwater welding is the thick gaseous bubble shield. A layer of bubbles surrounding the welding area reduces the electricity’s conductivity by as much as ten times, as the bubbles protect the electrode and weld.

This method not only protects the welder but is also useful in reducing the corrosion of the electrode from saltwater and other oxidizing compounds.

In conclusion, underwater welding is a hazardous job that requires expert knowledge to prevent electric shock and other severe injuries. A fully insulated electrode and a thick gaseous bubble shield are two methods used to safeguard the welder in the process. These safety measures ensure that underwater welding is completed safely and successfully.

How Does Underwater Welding Work?

Underwater welders don’t get electrocuted because they use a thick layer of gaseous bubbles externally around the electrode, covering the weld and shielding the electricity from water, corrosive gases, and other oxidizing compounds. This prevents current from passing through the welder’s body.

As underwater welding continues to gain popularity in various industries, one question remains on the minds of many people – how does underwater welding work? Underwater welding is a challenging task, but thanks to technological advancements, it is now easier to weld underwater without risking the life of the underwater welders.

In this article, we will take a closer look at how underwater welding works, with a particular focus on electrodes and workpieces, isolated circuits, and bubble shielding.

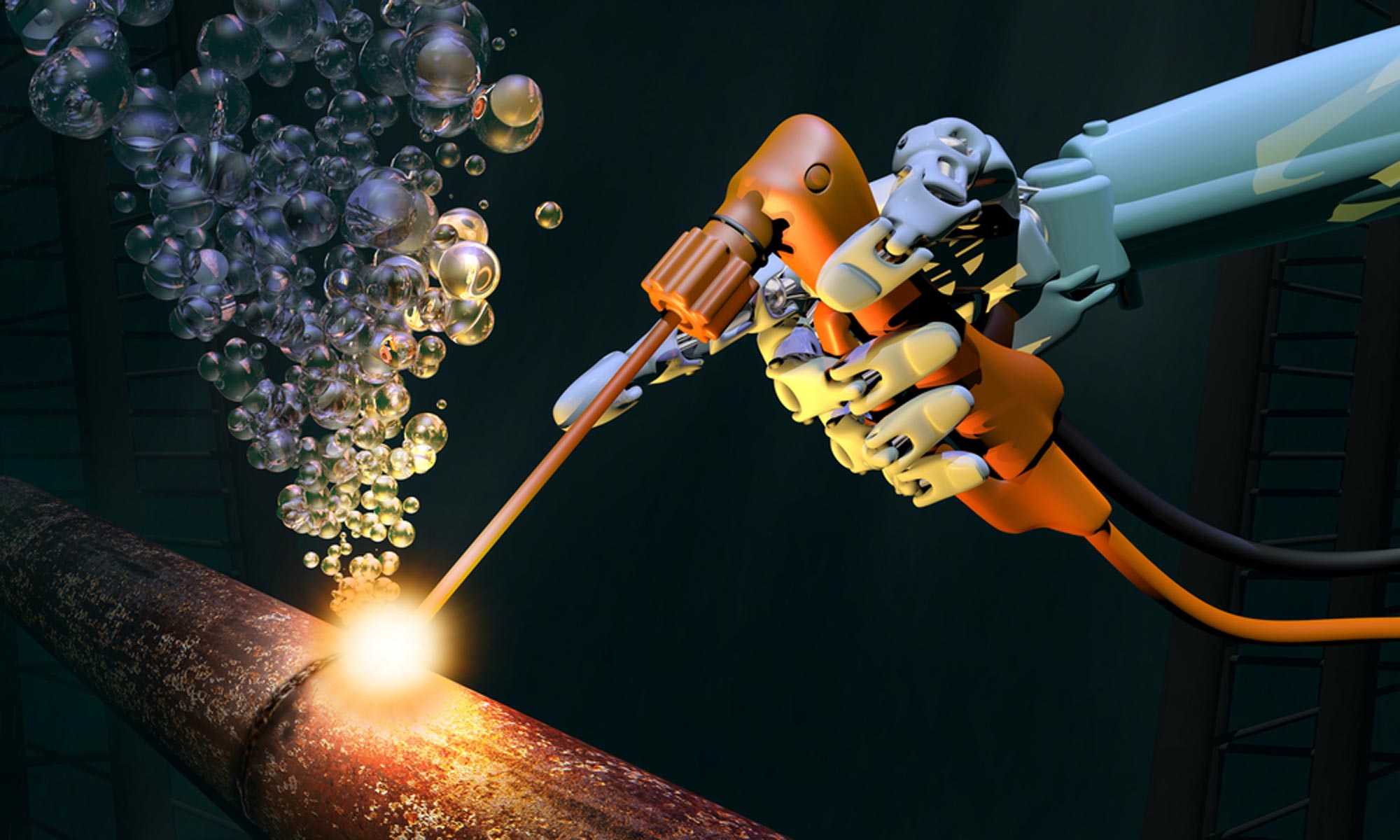

Electrodes And Workpiece

For underwater welding to work, a welder must have two crucial components – an electrode and a workpiece. The electrode, which is a metallic rod, produces an electric arc that heats the metal workpiece to its melting point. The electric arc, which conducts electricity, is created when the electrode is brought close to the workpiece.

Isolated Circuit

Since water is an excellent conductor of electricity, underwater welding can be dangerous. To prevent electrocution, welders create an isolated circuit that ensures that electric current flows only between the electrode and the workpiece. The circuit is isolated by attaching a cable from the generator to the welding machine and then to the welding electrode.

Bubble Shielding

Another vital aspect of underwater welding is bubble shielding. To prevent underwater welders from being electrocuted, a thick layer of gaseous bubbles is created externally around the electrode, covering the weld, and shielding the electricity from water, corrosive gases, and other oxidizing compounds.

The bubble shield is created by releasing a supply of compressed gas through small holes in the electrode holder to surround the electrode.

In conclusion, by using an electrode and a workpiece, creating an isolated circuit, and bubble shielding, underwater welding has become a safer and more effective method of welding in various industries.

By adhering to these techniques, underwater welders can work efficiently and confidently without risking their lives.

Credit: m.youtube.com

Safety Tips For Underwater Welding

Underwater welders don’t get electrocuted because the electrode used for welding is surrounded by a thick layer of gaseous bubbles that cover and shield the weld from water, corrosive gases, and other oxidizing compounds.

This external layer prevents the electricity from coming into contact with the welder’s body, ensuring their safety while carrying out their job.

Underwater welding is a dangerous profession, and it is vital to equip yourself with safety tips and guidelines to ensure your safety and well-being. The following are some essential safety tips for underwater welding:

Training And Qualifications

It is crucial to get proper training and education before attempting any underwater welding job. Every welder must hold a certificate of completion from a recognized and accredited school.

Regular Inspections

Inspections should be carried out regularly to ensure all equipment and tools used during underwater welding are in good condition. These inspections must include checking the diving gears, welding equipment, and electrical cables.

Emergency Planning

It is essential to have an emergency plan in place before diving into the water. The plan should include equipment and procedures for responding to emergencies such as electric shock, hypothermia, and decompression sickness.

| Safety Tips | Description |

|---|---|

| Training and Qualifications | Get proper training and education before attempting any underwater welding job. |

| Regular Inspections | Carry out inspections regularly to ensure that all equipment and tools used during underwater welding are in good condition. |

| Emergency Planning | Always have an emergency plan in place before diving into the water. |

| Welding Technique | Ensure tight fittings and avoid direct contact with the metal while welding. |

| Personal Protective Equipment | Wear waterproof gloves, boots, and goggles to protect yourself from electrocution. |

Welding Technique

Welders should ensure that all fittings are tight to prevent leaks. Also, avoid direct contact with the metal while welding, which can cause electric shock.

Personal Protective Equipment

Wear proper personal protective equipment such as waterproof gloves, boots, and goggles to protect yourself from electrocution. This equipment should be tested regularly and be a vital part of the emergency plan.

By adhering to these safety tips and guidelines, you can minimize the risk of accidents, injury, and death while working as an underwater welder. Always remember that safety comes first, and no amount of hurry can outweigh the need to follow safety regulations and protocols.

Electric Shock In Welding

Underwater welders don’t get electrocuted because a thick layer of gaseous bubbles is created externally around the electrode, covering the weld and shielding the electricity from water, corrosive gases, and other oxidizing compounds.

This method helps to prevent electric shock, which is the biggest threat to underwater welders and requires special waterproof equipment that is tested and used for all underwater welding jobs.

Electric Shock in Welding

Electric shock is arguably the biggest threat to the safety of underwater welders. Unlike regular arc welding, underwater welding poses unique hazards as electric currents can easily flow through water, making it easier to get shocked. However, protective measures have been put in place to mitigate this risk, ensuring that underwater welders can carry out their jobs with minimum danger.

Causes of Electric Shock

Electric shock in welding can occur for a variety of reasons. One common cause is insufficient insulation on the welding equipment. In this case, electrical currents can flow through the water to the welder, resulting in a shock. Another cause of electric shock during welding is improper grounding.

If the welding equipment is not properly grounded, it can cause an electrical current to flow through the welder and lead to an electric shock. It is therefore important to ensure that there is proper insulation and grounding to prevent electric shock while welding underwater.

Symptoms of Electric Shock

Electric shock can be life-threatening and may cause a range of symptoms. In some cases, it can cause cardiac arrest, leading to death. Other symptoms may include burns, muscle contractions, numbness, and paralysis.

It is important to note that the severity of the symptoms depends on the intensity, duration, and frequency of the shock. Therefore, it is important to recognize the signs of electric shock and seek medical attention immediately.

Preventing Electric Shock

To prevent electric shock while underwater welding, it is essential to use proper safety equipment and techniques. The welding equipment used for underwater welding must be specially designed to withstand the harsh underwater environment.

The welding current used must be low enough to prevent electric shock or electrocution. Furthermore, it is important to carry out regular inspections and maintenance of the welding equipment and ensure that it conforms to safety standards.

Lastly, proper training and certification for underwater welders and their supervisors are also crucial in preventing electric shock and promoting safety.

In conclusion, while electric shock remains a significant hazard in underwater welding, it can be prevented through proper insulation, grounding, safety equipment, and techniques. With the right safety measures put in place, underwater welders can carry out their jobs safely and efficiently without fearing electric shock or electrocution.

Credit: www.reddit.com

Credit: www.scuba.com

Frequently Asked Questions On Why Don’t Underwater Welders Get Electrocuted

Why Do Underwater Welders Not Live Long?

Underwater welders face several dangers that may cause severe injuries or even death. The formation of gas pockets underwater, which may explode, is one of the risks. Additionally, decompression sickness due to rapid pressure changes may lead to severe health problems.

However, the primary danger that underwater welders face is due to electric shock, making it crucial to use waterproof equipment.

How Do You Weld Under Water Without Getting Shocked?

Underwater welders can prevent electric shock by creating a thick layer of gaseous bubbles around the electrode, which covers the weld. This shields the electricity from water, corrosive gases, and other oxidizing compounds. Special waterproof equipment must be tested and used for all underwater welding jobs to prevent electric shock, which is the biggest threat to underwater welders.

What Is The Number One Cause Of Death For Underwater Welders?

The number one cause of death for underwater welders is explosions caused by the formation of gas pockets from hydrogen and oxygen. Electric shock is also a significant threat, which is why specialized waterproof equipment must be used for all underwater welding jobs.

Do Underwater Welders Get Attacked By Sharks?

While underwater welding, the chances of shark attacks are minor since sharks typically do not attack divers. However, sea life may interrupt the process. Underwater welders are not electrocuted due to the creation of a thick layer of gaseous bubbles around the electrode, which shields the electricity from water and other oxidizing compounds. Special waterproof equipment is also used to prevent electric shock.

How Do Divers Avoid Electrocution During Underwater Welding?

Underwater welders are shielded from electricity using a layer of gaseous bubbles around the electrode, which protects them from corrosive gases and other oxidizing compounds.

Conclusion

Underwater welding can be a challenging and risky profession, but the use of special equipment and techniques has made it safer for welders. By creating a thick layer of gaseous bubbles around the electrode, the electricity is shielded from water and other corrosive elements, preventing electrocution.

While there are still other hazards like gas explosions and decompression sickness, proper training, and precautions can greatly reduce the risks. Overall, underwater welding is a specialized skill that requires knowledge and expertise, and with the right safety measures, it can be performed efficiently and safely.