What Does F And G Mean in Welding => F stands for fillet weld, while G is a groove weld. A fillet weld joins together two pieces of metal that are perpendicular or at an angle, while a groove weld is made in a groove between workpieces or between workpiece edges.

These symbols are used in welding to indicate the type of weld joint and help the welder understand the specifications of the welding job. Understanding the meanings of F and G in welding is important for ensuring the correct welding technique and achieving a strong and durable weld.

We will explore in more detail what F and G mean in welding and how they are used in different welding positions and applications.

Understanding Welding Symbols

Overview Of Welding Symbols And Their Importance

Welding symbols are a crucial part of the welding process, as they provide a standardized way to communicate important information about a weld joint. These symbols are like a universal language, understood by welders, inspectors, and engineers alike. They convey essential details such as the type of weld, its dimensions, and the required welding technique.

Brief Explanation Of The Significance Of F And G Symbols In Welding

When it comes to welding symbols, two common symbols used are F and G. These symbols represent specific types of welds and play a crucial role in understanding the welding process.

The F symbol stands for a fillet weld. Fillet welds are used to join two pieces of metal that are perpendicular or at an angle. They are commonly used in various applications, including structural fabrication, automotive manufacturing, and shipbuilding. Fillet welds are known for their strength and ability to distribute stress evenly along the joint.

The G symbol, on the other hand, represents a groove weld. Groove welds are made in a groove between workpieces or between workpiece edges. They are typically used when a stronger and more secure bond is required, such as in pressure vessels, pipelines, and heavy machinery.

| Symbol | Weld Type | Application |

|---|---|---|

| F | Fillet Weld | Structural fabrication, automotive manufacturing, shipbuilding |

| G | Groove Weld | Pressure vessels, pipelines, heavy machinery |

Understanding these symbols is crucial for welders, as they provide important information about the required welding technique and joint geometry. They allow welders to follow the correct welding procedure and ensure the weld meets the specified requirements.

In conclusion, the F and G symbols in welding represent two important types of welds: fillet welds and groove welds. By understanding these symbols, welders can ensure they apply the correct welding technique and achieve high-quality weld joints.

F Symbol In Welding

When it comes to welding, there are various symbols and abbreviations used to represent different weld joints and positions. One commonly used symbol is the F symbol, which stands for fillet weld. In this section, we will explore the meaning and significance of the F symbol in welding.

Definition Of F Symbol In Welding

The F symbol in welding represents a fillet weld. A fillet weld is a type of weld joint where two pieces of metal are joined together in a corner. This corner can be perpendicular or at an angle. The fillet weld is used to provide strength and reinforce the joint.

Explanation Of The Role Of F Symbol In Weld Joints

The F symbol plays a vital role in identifying and specifying the type of weld joint required for a particular application. By using the F symbol, welders can quickly understand the type of weld joint needed and ensure that the appropriate technique is used. Fillet welds are commonly used in structural applications, such as building construction, bridges, and supports.

Examples Of Weld Joints That Use The F Symbol

There are several examples of weld joints that utilize the F symbol. Some common examples include:

- Fillet welds are used to join two plates at a right angle.

- Fillet welds are used to connect a plate to the edge of a beam.

- Fillet welds are used to attach braces or stiffeners to a structure.

- Fillet welds are used to secure corner joints in sheet metal fabrication.

These are just a few examples, and the F symbol can be used in various other weld joints depending on the specific application and design requirements.

G Symbol In Welding

In the field of welding, the use of various symbols is crucial for ensuring proper understanding and interpretation of weld joints. One such symbol is the G symbol, which plays a significant role in welding processes. In this section, we will explore the definition of the G symbol in welding, its role in weld joints, and provide examples of weld joints that utilize the G symbol.

Definition Of G Symbol In Welding

The G symbol in welding represents a groove weld. The G symbol denotes that the weld is made in a groove between workpieces or between workpiece edges. Groove welds are commonly used when joining two pieces of metal that require a stronger and more secure bond, especially in structural applications.

Explanation Of The Role Of G Symbol In Weld Joints

The G symbol is used to specify the type of weld joint required in a welding project. By using the G symbol, welders can easily understand the necessary groove weld for a particular application. This symbol helps ensure that the welders achieve the desired strength and integrity in the joints, as well as adhere to the project’s specifications.

Additionally, the G symbol provides crucial information about the welding process, including the dimensions and preparation of the groove, the type of welding filler material to be used, and any other specific requirements for the weld joint.

Examples Of Weld Joints That Use The G Symbol

Several weld joints utilize the G symbol in welding. Some examples include:

- A butt joint between two metal plates that require a strong, full penetration weld.

- A T-joint is where one piece of metal is welded onto the surface of another metal.

- A corner joint between two metal sheets that meet at a right angle.

In each of these examples, the G symbol is used to indicate the need for a groove weld. This type of weld provides enhanced strength and durability, making it suitable for various applications across industries such as construction, automotive, and manufacturing.

Overall, the G symbol in welding plays a vital role in ensuring the proper execution of weld joints. By correctly interpreting and applying this symbol, welders can achieve strong and reliable connections between metal workpieces, contributing to the overall quality and safety of welding projects.

Credit: www.wpafb.af.mil

Difference Between F And G Symbols

Detailed Comparison Of F And G Symbols In Welding

The symbols F and G are commonly used in welding to represent different types of weld joints. Understanding the difference between these symbols is crucial for accurate interpretation and execution of welding tasks.

Explanation Of When To Use F Symbol And When To Use G Symbol

The F symbol stands for fillet weld, which is used to join two pieces of metal that are perpendicular or at an angle. Fillet welds are commonly used in situations where the joint does not require full penetration. On the other hand, the G symbol represents a groove weld. A groove weld is made in the groove between workpieces or between workpiece edges and provides a stronger and more durable joint.

Examples Showcasing The Difference Between F And G Weld Joints

| Weld Joint | Symbol | Description |

|---|---|---|

| Fillet Weld | F | Used to join two pieces of metal that are perpendicular or at an angle |

| Groove Weld | G | Made in the groove between workpieces or between workpiece edges |

- Example 1: If you are joining two metal plates that are perpendicular to each other, you would use an F symbol for a fillet weld.

- Example 2: On the other hand, if you are joining two metal plates that have a groove between them, you would use a G symbol for a groove weld.

By understanding the difference between the F and G symbols, welders can accurately interpret welding blueprints and execute welds that meet the required specifications.

Applications Of F And G Weld Joints

Discussion On The Various Applications Of F And G Weld Joints

When it comes to welding, understanding the different types of weld joints is crucial for successful and efficient welding processes. Two commonly used weld joints are F and G weld joints, each with its unique applications. F stands for fillet weld, while G represents groove weld. Let’s explore the applications of these weld joints in various industries and projects.

Examples Of Industries Or Projects That Commonly Use F And G Weld Joints

Fillet Weld (F) – It is a welding method used for combining two parts of metal vertically or slightly at an angle. This type of weld joint is widely employed in industries such as:

- Construction: Fillet welds are commonly used to join structural steel components, such as beams, columns, and trusses.

- Automotive: F-weld joints are found in automobile manufacturing, particularly when joining sheet metal or forming strong connections between metal components.

- Shipbuilding: Fillet welds are extensively used in shipbuilding for joining various metal sections and providing structural integrity.

- Aerospace: F weld joints are employed in the aerospace industry for joining metal components, ensuring strength and stability in aircraft structures.

- Manufacturing: Many manufacturing processes rely on fillet welds, such as fabricating machinery, equipment, and consumer goods.

Groove Weld (G) – It is a weld made within a groove, usually between workpieces or workpiece edges. This type of weld joint finds widespread usage in industries such as:

- Pipeline Construction: Groove welds are commonly used for joining various sections of pipelines, providing a strong and leak-free connection.

- Heavy Engineering: G weld joints find applications in heavy engineering projects, such as bridges, power plants, and infrastructure development.

- Pressure Vessel Fabrication: Groove welds are crucial for creating pressure vessels, ensuring safe containment of various materials.

- Fabrication of Structural Steel: G weld joints play a vital role in the fabrication of structural steel, including buildings, bridges, and industrial structures.

- Oil and Gas Industry: Groove welds are extensively used in oil and gas pipelines, platforms, and refineries for reliable and durable connections.

Understanding the applications of F and G weld joints allows welders, engineers, and professionals in various industries to determine the most suitable weld joint for specific projects. By choosing the appropriate weld joint, they can ensure the structural integrity, strength, and durability of welded components.

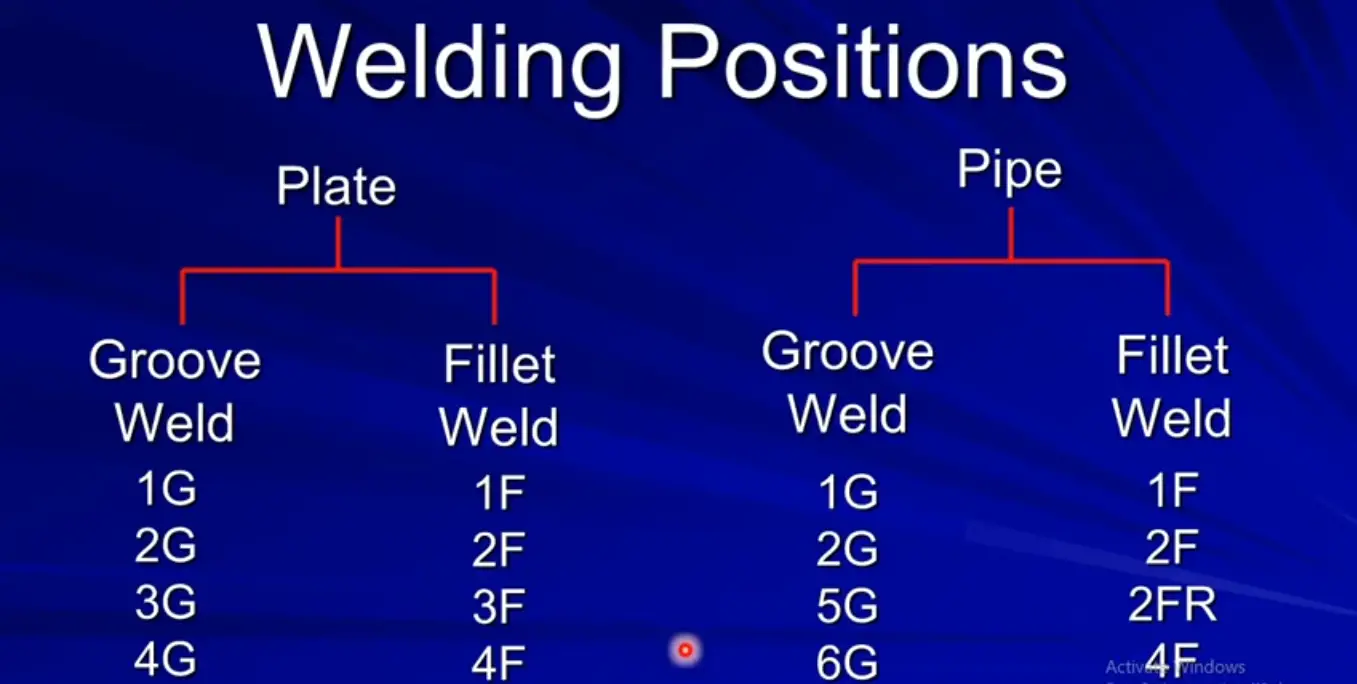

Understanding Welding Positions

Introduction To Welding Positions And Their Importance

Welding positions play a vital role in the welding industry as they determine how a weld joint is oriented. The specific welding position used for a project affects the quality, strength, and appearance of the weld. Different welding positions are defined by a combination of letters and numbers, with the letters F and G being commonly seen. Understanding these positions is crucial for welders, as it allows them to perform their work efficiently and ensure that the welds meet the required standards.

Explanation Of How Welding Positions Relate To F And G Symbols

In welding, the symbols F and G refer to specific welding positions. F stands for fillet weld, while G represents groove weld. A fillet weld joins together two pieces of metal that are perpendicular or at an angle, creating a triangular shape. On the other hand, a groove weld is made in a groove between workpieces or between workpiece edges. The F and G symbols indicate the type of weld that should be performed in a particular welding position.

Overview Of The Different Welding Positions And Their Characteristics

Each welding position has its unique characteristics and requirements. Here are some common welding positions and their brief descriptions:

- 1G Position (Flat Position): The weld axis is horizontal, and the welder can work from the top. This position is often used for flat joints.

- 2G Position (Horizontal Position): The weld axis is vertical, and the welder performs the welding from the side. This position is suitable for welding horizontal joints.

- 3G Position (Vertical Position): The weld axis is horizontal, and the welder works from the top. This position is used for upright joints, such as welding on vertical plates.

- 4G Position (Overhead Position): The weld axis is vertical, and the welder welds from the bottom. This position is challenging and is used for welding overhead joints.

These are just a few examples of welding positions, and there are many more variations depending on the specific project requirements.

By understanding the welding positions and their associated symbols (F and G), welders can ensure that they select the appropriate position and perform the correct type of weld. This knowledge is essential for producing high-quality welds that meet the desired standards.

Frequently Asked Questions Of What Does F And G Mean In Welding?

What Is The G Symbol In Welding?

The G symbol in welding stands for groove weld, while F stands for fillet weld. A groove weld is made in the groove between workpieces or workpiece edges, while a fillet weld joins two pieces of metal that are perpendicular or at an angle.

What Is The Difference Between 2g And 2f Welding?

F stands for fillet weld, while G represents groove weld in welding. A fillet weld joins two metal pieces perpendicular or at an angle, while a groove weld is made in a groove between workpieces or workpiece edges.

What do the following Welding Symbols Stand For 1f Or 1g?

F stands for fillet weld, while G represents groove weld in welding symbols. Fillet weld connects two metal pieces at an angle, while groove weld is made in a groove between workpieces or their edges.

What Is 6g Welding?

6G welding refers to a specific welding position where the pipe is fixed at a 45-degree angle. The number 6 represents the fixed position, while the letter G stands for the type of weld joint, which is a groove weld.

What Does The Welding Symbol “g” Stand For?

The symbol “G” in welding stands for groove weld, which is made in the groove between workpieces or workpiece edges.

Conclusion

To summarize, in the world of welding, F stands for fillet weld and G stands for groove weld. A fillet weld is used to join two perpendicular or angled pieces of metal together, while a groove weld is made in the groove between workpieces or workpiece edges.

These symbols indicate the type of weld joint and are essential for understanding welding blueprints and specifications. By knowing the meanings of F and G, welders can accurately interpret welding symbols and perform their work accordingly.